Conversation / Michael Marriott and DYN-Metal

Designer Michael Marriott and Max Limbourg of DYN-Metal discuss the creation of STOPP, a machined bronze doorstop for London's Kitchen.

March 2023

In 2021 Panel presented London’s Kitchen, a limited-edition collection of six products connected to and inspired by Park Royal, a large industrial area located in North West London.

Made through partnership between artists and designers with local businesses in and around the area, the products reflect Park Royal’s character, its links and its changing industrial heritage; from a centre of manufacturing to a place of material transformations, of goods imported and exported and hands passed through.

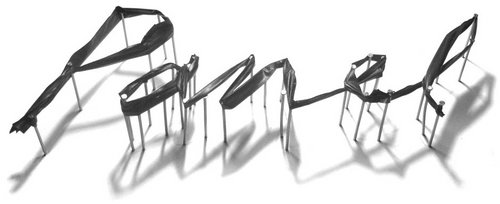

For London’s Kitchen, Michael Marriott partnered with local foundry DYN-Metal to create STOPP, a machined bronze doorstop.

Michael, why did you want to work with DYN-Metal to create your product for Park Royal?

MM: I was immediately intrigued by DYN and their highly specialist processing, which is so particular to their world. They manufacture and process a range of super high specification bronzes, from their foundry in Park Royal, for use as bushes and bearings in a gamut of diverse applications. Bronze, a supremely beautiful and heavy material, with such specific properties, makes it the foremost choice for bushings and bearings, but it’s also the traditional material for sculpture casting.

In both instances though, you rarely see the raw material. Sculptures are typically patinated dark brown, or in the hands of Jasper Johns, and many artists since, painted to represent something else, such as two beer cans. When used for bushings and bearings, the bronze is relegated to a hidden service role within the depths of some mechanical contraption, such as a tube station escalator.

So, with all this in mind, I wanted to make something that would utilise the inherent weight and beauty of bronze and take advantage of the machine processing that DYN-Metal are so expert at. Their materials are either extruded or centrifugally cast, into very fat-walled tubes of various dimensions. These ‘tubes’ provide the primary form for the bushes and bearings they make. Utilising this ‘doughnutlike’ readymade form, with a little precision machining to make a kind of hefty foot, seemed to make sense for the main element of the doorstop — but to make it easy to move, it should have a handle.

I decided to juxtapose the crisp machined bronze with a much more prosaic material for the handle — mild steel re-bar. This is another material usually hidden from view, inside cast concrete floors or columns, and, although a hard-core utility stock, has a tactility, which makes it suit being the point of contact with your hand when moving the doorstop.

Did visiting the DYN-Metal foundry help to form your ideas for the product?

MM: I had an approximate idea of what they did, but visiting them was great, I experienced their very specific way of centrifugally casting bronze tubes, which is the main material they work with, so my design was very much based on this specialisation.

DYN-Metal was founded in London in 1937. Max, can you tell us about its founders and how they came to establish DYN?

ML: DYN was founded by Jewish émigrés in 1937. The company initially started with the office and works separated – the office in Victoria and the works underneath the railway arches in Camden Town, now a craft brewery and opposite a luxury hotel. In the 1930s, the founders discovered and developed a process that resulted in a dramatic improvement in the wear life of bronze alloys. This process led to the development of a unique range of wear-resistant alloys that have proven to offer typically a threefold improvement in life over untreated alloys of the same composition.

DYN are long-time residents of Park Royal, moving there in 1977. How has the area changed over the years?

ML: Most other heavy industry has left Park Royal over the years. When DYN moved to Park Royal it was an ideal location near many subcontracting companies and customers. Now we have hardly any customers left within London and mostly supply to companies in the remaining industrial centres in the UK and abroad. Former large industrial sites have been converted into numerous smaller units, with a large focus on food processing, but also warehousing due to the areas’ proximity to Central London. In addition, over the last 10 years, the area around North Acton has developed from a petrol station and warehouses to a cluster of high-rise tower blocks. Despite this radical change, we are committed to our Park Royal works and have made further investments to machinery since the production of the STOPP doorstop.

How did working in partnership with Michael on a limited-edition artist’s product differ to the work you usually undertake?

ML: We usually only supply bespoke bearings for industrial applications, so working with Michael was a very interesting experience. He was very keen to reflect the industrial character of our products in the design of his doorstop. We usually work to very tight tolerances and our entire production is centred around quality. The manufacturing process of the doorstop followed our strict quality assurance procedures. After the finish machining on our Mazak Integrex CNC was completed, every item was inspected on our brand new Aberlink Horizon CMM, just like any other part that would leave our machine shop. So, from a manufacturing point of view the process didn’t differ from other products we make. Of course, the choice of alloy was based on aesthetic reasons rather than required wear properties.

Michael, you mentioned this often-concealed nature of bronze, and its application within industry, within your design. How does the concept of visibility/invisibility, and use of prefabricated elements, play out in STOPP and in your work more widely?

MM: I kind of feel like so much design is about hiding the making of things or the fixings, and it often results in stylish/stylised objects which have little relation to other things except passing fashions. I’ve always loved the found and readymade, their relationship to Marcel Duchamp and Achille Castiglioni, but also existing objects have a useful familiarity, and are so loaded and so often ripe for re-invention. And I think there’s something delightful in seeing something being mis-used or re-used. Proper human resourcefulness.

Michael Marriott is a designer who works in lots of different ways and makes lots of different things, often using ordinary elements like wing nuts and plastic buckets and combining these with new, reclaimed or found materials ranging from oak to plywood and peg-board. His work is characterised by a pared back functionalism and a supremely honest approach to materials, forming objects which have a pure structural logic, and are thought-provoking as much as pleasing to the eye. Michael has designed products for a range of clients including Very Good & Proper, Established & Sons & SCP, as well as for his own webshop, woodmetalplastic.com.

DYN-Metal is a specialist non-ferrous foundry and machinist company, producing copper-based alloys that offer unique benefits solving sliding wear problems in mechanical systems, operating in the heavy engineering sector. DYN-Metal owes its very existence to the discovery and development in the 1930’s, by its founders, of a process that resulted in a dramatic improvement in the wear life of bronze alloys. This process has led to the development of a unique range of wear resistant alloys that have proven to offer typically a three-fold improvement in life over untreated alloys of the same composition. Since establishing in London in 1937 (locating to Park Royal in 1977), the company has progressed and adapted to changes to the UK manufacturing Industry, moving from producing solely processed alloy ingots to products in the form of cast rod, tube and plate and machining castings into finished items such as bearing bushes and slide plates. As such, the company now boasts a very well equipped machine shop embracing the latest CNC machines operating up to 5 axes. As a result, though DYN-Metal is a small SME, it enjoys strong working relationships with ’Blue Chip’ companies operating in the Manufacturing and Maritime sectors of Heavy Engineering. www.dynmetal.co.uk

STOPP is now sold out. Browse the other London’s Kitchen commissioned products here.

Watch the short film, In Production at DYN-Metal here.

For more information about the project, see www.londonskitchen.com

Interview by Laura Richmond